Why is called a 4 stroke engine, because there are four steps. Here are the details of each process. To make it easy, then your email settings to HTML, so images will appear sequentially. Images taken from the website www.howstuffworks.com / engine.htm. On this website, the image seen moving. But for the sake of simplicity, the picture intentionally set of steps.

1. Intake Called the intake step because the first step is to suck through the piston from the carburetor. Fuel supply is not enough just from the spray carburetor. The way it works is as follows. First piston at the top position (or called Dead Spot On). Then the piston to suck the fuel that already gives a chance / mixed between gasoline and air in the carburetor. The piston then retreated to suck fuel. To open, the necessary valve or inlet valve that will open when the piston down / sucked downward.

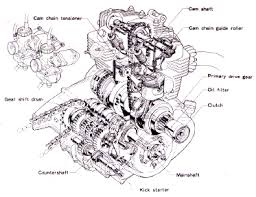

Movement is governed by the inlet valve or a mechanical camshaft. Namely, camshaft valves regulate the amount of opening by pressing a lever valve. Own camshaft driven by keteng chain which is connected between the camshaft to the crankshaft. For details, see the following figure.

Notice that A is the Intake Valve (valve into the fuel) and the valve is pressed (opening) because I (camshaft), pressing the valve A. Thus, when the piston descends, then A is open at the same time the fuel drawn into the combustion chamber. A will cover a certain extent before the second step: compression. Keteng chain is not visible because it will be difficult pictured above, but the crankshaft (P) is connected with the camshaft (I). Some European cars like Mercedes use the chain as a liaison between the crankshaft and camshaft, but mostly in Japanese cars use belts that we know as the timing belt.

2. Compression This step is a continuation of the steps above. After the piston reaches the lowest point in the phase of intake, and intake valve is closed, and the compression process. Namely, the existing fuel in the combustion chamber is compressed. The room was shut tight because the two valves (intake and exhaust) is closed. This process continued until the bursting of the following steps in step 3 spark plugs.

3. Combustion (Combustion)

The following stage is the spark plug at some point it will explode after PISTON STOP MOVING OFF TO ACHIEVE AND REVERSE A FEW DEGREES. So, do not explode when the spark plug piston at top point (called a point of 0 degrees), but the piston back up, just exploded. This is because to avoid the energy wasted because when the piston at top dead point, there is still latent energy (that is saved due to urge the compression process). If at the point of 0 degrees spark to explode, could be the piston back but mengengkol crankshaft to the rear (the motor backwards, not turn the wheel to the front).

After the burning process, the piston has the energy to push the crankshaft which will be channeled through the gearbox and the sprocket, chain, and lastly to the wheels.

4. Exhaust (Disposal)

The last step is done after burning. Due to the combustion piston is pushed down to the lowest point, or is called Bottom Dead Point. After that, the piston will be pushed to the front and exhaust valve open while the intake valve is closed. Therefore, the exhaust gas is pushed into the exhaust port hole (or we say the connection to the exhaust hole). Thus, we can discard all the rest of the exhaust gas due to combustion. And after the net again, and then we'll go back to repeat step 1 again.

No comments:

Post a Comment